Special products on customer needs

Experience and quality

Thanks to the experience gained in the design and construction of mechanical transmissions, Sorem now has a vast wealth of metallurgical and technological knowledge.

This valuable wealth of knowledge allows us to combine the range of double cardan joints , the company's core business, with the creation of special products ,

such as solar shafts , drive shafts , or power take-off shafts internal and external.

Special Sorem products are built to customer specifications and designs and incorporate the same high quality requirements of each Sorem product.

High flexibility, rapidity of development and construction and accurate laboratory analysis guarantee the perfect correspondence of our special products to the expectations of the most demanding customer.

Our technical department is ready to make its experts available to study the most suitable solutions to help the customer solve any problem in the field of mechanical power transmission.

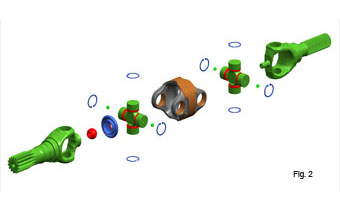

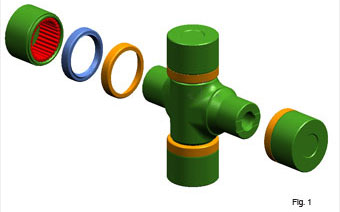

Design and manufacture of special products

Double joints with offset crosses

These types of cruise allow to transmit greater torques maintaining a lower axial dimension and a greater radial dimension. Sorem can provide double joints using offset crosses.Double self-supporting joints

Another special product are the double self-supporting joints used on bridges with independent suspension.These are much more complex products than classic double joints as they do not provide the classic supports but, through a sphere coupled to a pin, allow the joint to self-support.

This type of joint, in addition to carrying out the normal steering, also has the task of following the possible sinking of the wheels.

It should be remembered that this product is also used on machines where suspension is required by law.

Design of specific products based on customer needs

In some cases, our customers themselves ask us to propose the type of double joints to be used, and the quality therefore the size will be defined based on the parameters provided (machine weight, speed, wheel diameter, load, etc.).To carry out this task we use design tools ranging from drafting the drawing, to the calculation of finite elements, up to the creation of prototypes to be tested both on the bench and in the field.